News

-

Inconel™718 casting

Usually used for jet engine castings, high-speed body castings, land-based gas turbine castings, oilfield castings, rocket engine castings, spacecraft, nuclear reactor parts castings, pumps and low-temperature application castings. Incon...Views -

Recrystallization Nucleation of Single Crystal Nickel Base Superalloy Castings

introductionThe recrystallization phenomenon of single crystal nickel-based superalloys during solution heat treatment leads to high costs of investment in the single crystal casting industry. The nucleation of recrystallization is usual...Views -

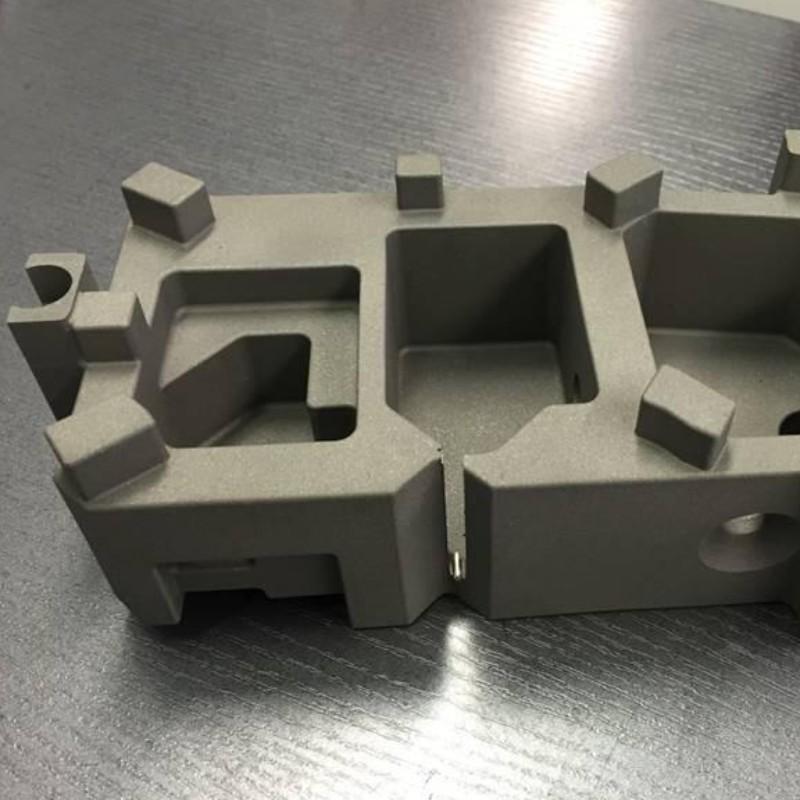

Three special requirements of casting method on casting structure

Three special requirements of casting method for casting structure (1) Investment castings: 1. Facilitate the manufacture of wax molds2. The holes and grooves on the castings should not be too small or too deep, too small or too de...Views -

Introduction and Application of Alloy R41 High Temperature Alloy Casting Materials

Alloy R41alloy R41, UNS N07041, Rene41, W.Nr.2.4665, Hyness alloy R41, J1610, carpenter41In the range of 650-900°C, it has high tensile and durable and creep strength and good oxidation resistance. It is suitable for manufacturing high ...Views -

Three special requirements of casting method on casting structure

Three special requirements of casting method for casting structure (1) Investment castings: 1. Facilitate the manufacture of wax molds2. The holes and grooves on the castings should not be too small or too deep, too small or too de...Views -

Introduction and Application of Inconel™600 Superalloy Casting Material

Inconel™600UNS NO6600, W.Nr.2.4816, alloy600, NA14Alloy 600 is a nickel-chromium-iron-based solid solution strengthened alloy with good high temperature corrosion and oxidation resistance, excellent cold and hot processing and welding p...Views -

High-temperature alloys Forging and casting high-temperature alloy technology research

High temperature alloys are divided into three types of materials: 760℃ high temperature materials, 1200℃ high temperature materials and 1500℃ high temperature materials, with a tensile strength of 800MPa. In other words, it refers to...Views -

Co-based alloy castings

Cobalt is a hard, shiny silver-gray metal that can be naturally protected from oxidation (rust) by a passivating oxide film. Like nickel, cobalt can only exist in nature in a chemically bonded form (natural alloy). Pure cobalt can be pro...Views -

Nickel-Based Metal Castings

We provide a variety of commonly used nickel-based metal casting alloys to meet customer needs for metal casting projects. When converting from previously designed forged parts to nickel-based castings, nickel-based metal castings can us...Views -

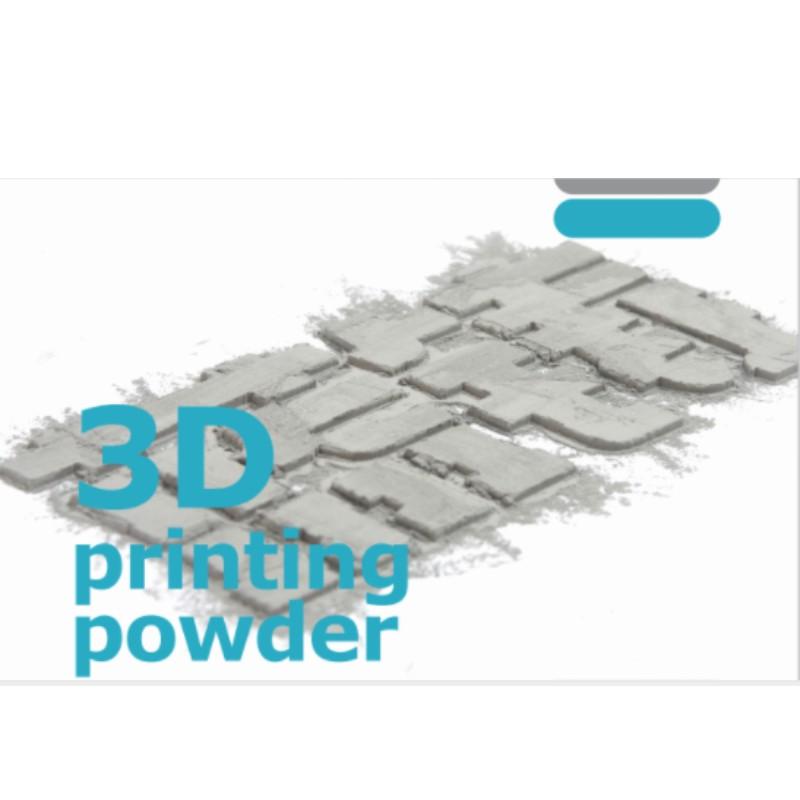

The metal 3D printing powder preparation method you must know

At present, the commonly used metal powder types in EBM and SLM technologies are:The preparation method generally includes the following: 1. Mechanical crushing method The solid metal mechanical pulverization method is an independent po...Views -

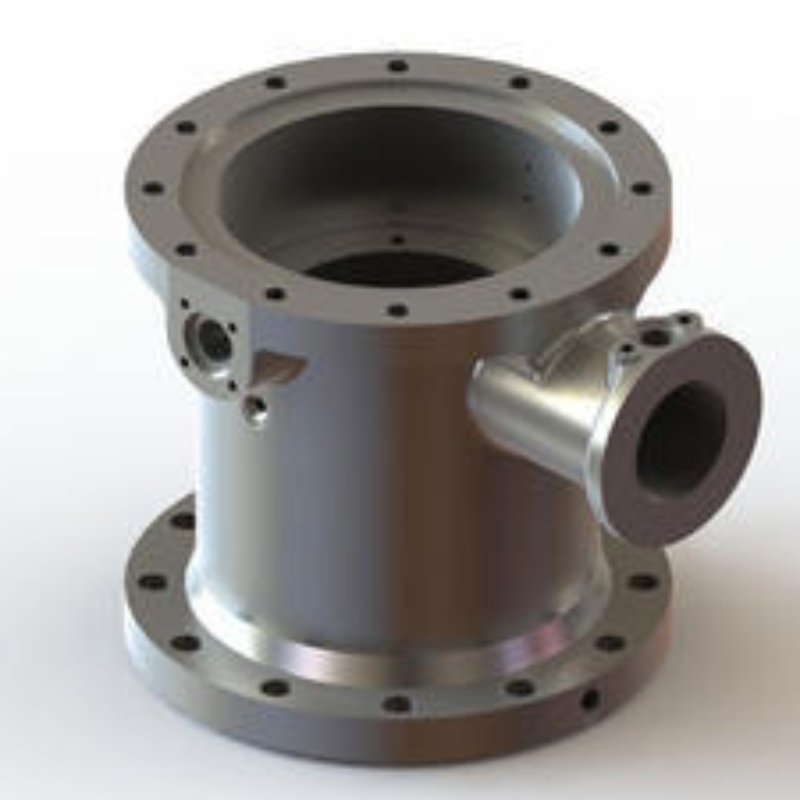

Inconel™713 impeller

The picture is Inconel™713 impeller,made in CONDLY.Alloy 713 is a precipitation hardening nickel-chromium-based casting alloy. It has excellent strength performance up to 1800ºF (980ºC). The alloy has good casting properties, and has ...Views -

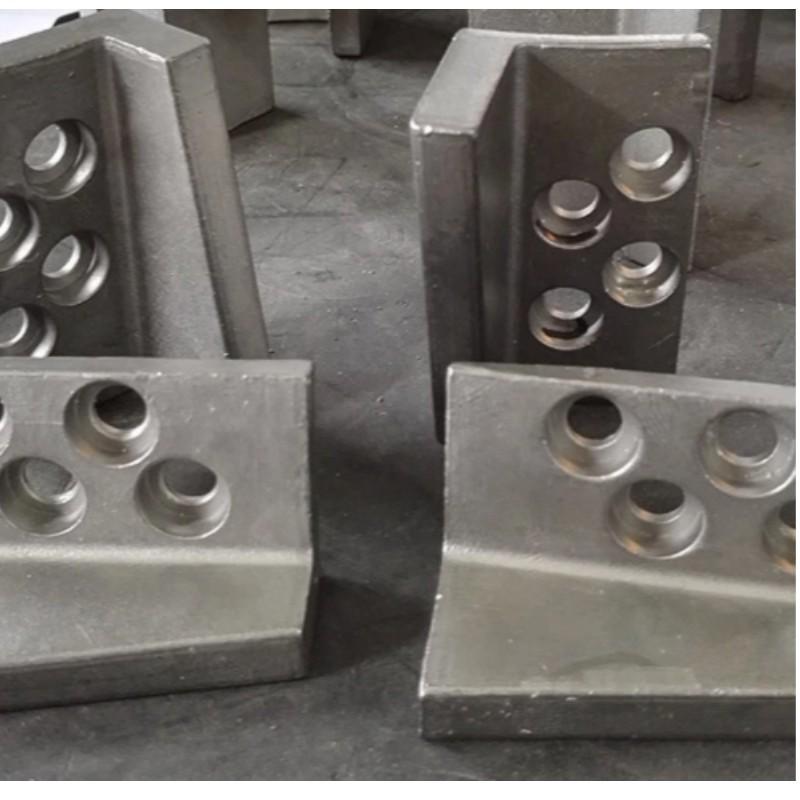

Cobalt alloy casing

Cobalt (Co)-based alloys (Stellite) are widely used in wear environments due to their good corrosion resistance, wear resistance and wear resistance.It is not only wear-resistant, but also corrosion-resistant, and can withstand high temp...Views