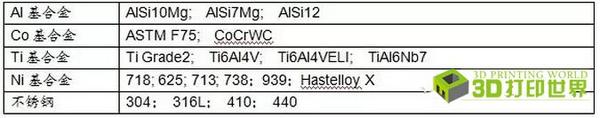

At present, the commonly used metal powder types in EBM and SLM technologies are:

The preparation method generally includes the following:

1. Mechanical crushing method

The solid metal mechanical pulverization method is an independent powdering method and can be used as a supplementary process for some powdering methods. That is, relying on crushing, crushing and grinding to crush bulk metals, alloys or compounds into powder. According to the final degree of crushing, it can be divided into coarse crushing and fine crushing.

If you want to further reduce or increase the powder size, alloying, etc., you can further choose mechanical grinding (such as: ball milling)

Applicable materials: Fe, Al, pure Ti powder and Fe-based alloys

2. Atomization method

The atomization method is a process in which liquid metals and alloys are directly broken into fine droplets, which are rapidly solidified to form powder. The high-speed air or water flow is not only the power for breaking the molten metal but also the coolant for the molten metal flow. Basically any material that can form liquid can be atomized.

For low melting point metal powders, the granulation process is to automatically inject molten metal into air or water through small holes or screens, and then condense to obtain metal powder. This method produces a coarser particle size;

Another method of preparing fine powder: water atomization or gas atomization; centrifugal atomization; and supersonic pulse inert gas atomization. Taking titanium alloy powder as an example, the titanium alloy powder is smelted and atomized into fine droplets by a high-purity argon gas stream, which descends under the action of gravity and passes through an inert gas stream, and solidifies the fine particles into powder under cooling.

Vacuum atomization method and inert gas atomization method are widely used at present (especially suitable for the preparation of active metal powder).

Applicable materials: Fe, Cu, refractory metals, stainless steel, Ti alloy, etc.

3. Reduction method

The "reduction method" is a method in which metal oxides and salts are reduced with a reducing agent to prepare metal powder, where the reducing agent can be solid, gaseous or liquid. Including carbon reduction method, gas reduction method, hydrogen reduction method, metal thermal reduction,

Suitable materials: rare metals and refractory metal powders represented by Fe, W, Ta, Zr

4. Vapor deposition method

is the use of metal vapor condensation, vapor-phase reducing agent chemical vapor deposition method. These materials are characterized by lower melting points and higher volatility.

Principle: Including chemical vapor method and physical vapor method. Electric explosive metal titanium wire can prepare nano spherical titanium powder

5. Electrolysis

The method of depositing powder from the cathode of an electrolytic cell under certain conditions. The electrolysis method is second only to the reduction method in frequency of use. Although the manufacturing cost is high, its preparation purity is also high, and it has a similar purification effect on metal powder.

Principle: Chemical electrolysis

Applicable materials: Fe, Cu, Ni, Ti and other metal powders, and intermetallic compounds

6. Rotating electrode method

The largest and most representative preparation method of superalloy powder at present: plasma rotating electrode powder method (ie PREP method), which prepares the powder with good shape (spherical), less pore powder, and low oxygen content. This method has high cost and is generally suitable for aerospace and biomedical fields.

Principle: A plasma gun is used to generate a plasma stream in a sealed atomization chamber to melt the end of the high-speed rotating alloy bar motor, and the liquid metal is atomized into very small droplets under the action of centrifugal force, and then cooled in an inert gas.

Applicable materials: Ni-based and other refractory metals, Ti and other active metals

7. Spheroidization method

spheroidization methods mainly include: radio frequency plasma spheroidization, laser plasma spheroidization and spheroidization with other heat sources

Principle: Take plasma spheroidization as an example: the irregularly shaped titanium powder particles are mixed with inert gas into the plasma torch, and the plasma torch is rapidly heated and melted. Under the action of surface tension, the molten particles form highly spherical droplets , In a very short time to quickly cool to obtain spherical powder.

Applicable materials: Mainly used for secondary processing of irregular metal powder.