Products

Inconel™738 precision casting,Production process of silica sol(K438)

Five Advantages Of Products

- Has good lasting strength

- Has good creep properties

- Has good oxidation resistance

- High corrosion resistance

- Has the best comprehensive mechanical properties

Product Details

Compared with many high-strength superalloys with lower chromium content, In 738 has an excellent combination of high-temperature creep rupture strength and corrosion resistance. In 738 is a nickel-based alloy that has undergone vacuum casting and precipitation hardening treatment and has excellent mechanical properties at high temperatures of 1800°F (982°C). IN-738 can withstand the high temperature and corrosive environment in the turbine industry.

Inconel™738 application field

• Making turbine rotor blades and guide blades

• Widely used for turbine working blades and guide blades of long-life ships and ground industrial gas turbines operating below 900°C.

• It can also be used as turbine parts for aero engines.

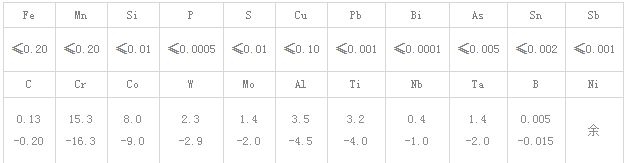

Inconel™738 Chemical Analysis

We are a direct manufacturer. Castings, pumps and valves can be customized according to drawings. Our most favorable specification is more than 5kg/piece, and there is no minimum minimum requirement. Users are welcome to try to order.

The capacity of our vacuum casting furnace is: 50kg, 100kg, 1000kg.

SHANGHAI CONLY VALVE CASTING CO., LTD

Contact Person: Una

Telephone: +86 17717022732

Landline: +86 021-5995 8756

Company Address: Building 5, No.2800 Caoxin Highway, Xuxing Town, Jiading District, Shanghai

Website: www.condlycasting.cn

Previous: Stellite®1 precision casting,Pro...

-

Hastelloy™C4 precision casting,Production process of sil...

-

Inconel™738 precision casting,Production process of sili...

-

Hastelloy™B2 precision casting,Production process of sil...

-

Monel™400 Precision casting, Production process of silic...

-

Incoloy™825 casting,Precision casting, Production proces...

-

Monel™K-500 precision casting, valve body casting, silic...

-

Inconel™713 precision casting, valve body casting, silic...

-

Incoloy™800H casting,Precision casting, Production proce...