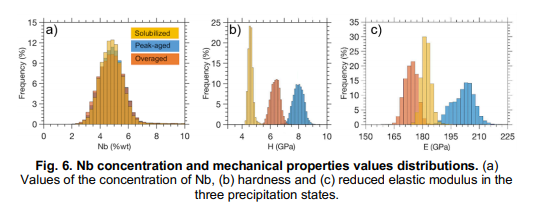

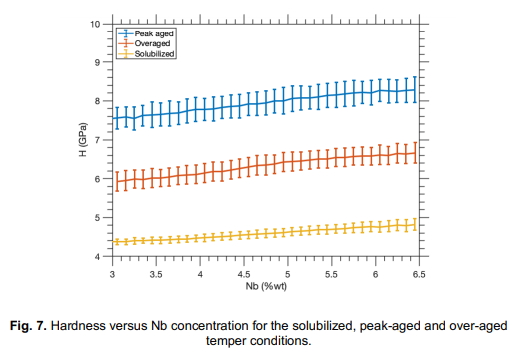

In fact, the hardness maps (Fig. 5a, b and c) reveal a direct correlation with the Nb content (Fig. 3s, t and u) and the temper condition. The histogram of hardness values in Fig. 6b show an average hardness of 4.7, 7.8 and 6.2 GPa for the solubilised, peak-aged and overaged temper conditions, respectively, as expected from the precipitation state of the alloy. But more importantly, the hardness dispersion provides valuable information on the role of the Nb content in each case. For instance, the solubilised state presents a narrower hardness distribution than the peak-aged and the overaged states. In other words, the width of the hardness distribution in the solubilized state is about 1-1.2 GPa, while it increases to around 2 GPa in the peak-aged and the overaged states. This can be confirmed comparing the hardness values in the core and the surface of the dendrites arms in Fig. 5a,b and c. Nb is expected to be mainly in solid solution in the solubilised state, with a lower fraction of �’’ strengthening precipitates with respect to the peak aged and overaged conditions. This indicates that Nb segregation leads to larger mechanical property variations in �’’ strengthened than in solid solution strengthened Ni based superalloys. Moreover, the Nb content and the hardness maps, containing over 16000 data points in each case, represent an statistically significant dataset from which quantitative correlations can be extracted between hardness and Nb content for each temper condition, as shown in Fig. 7. This information represents a very valuable local tool to assess the quality of welds, repairs or 3D printed components, as the local hardness maps can be directly correlated to the local microstructure, to identify areas with a strong Nb segregation or with local tempers, as a result of heat affected zones.

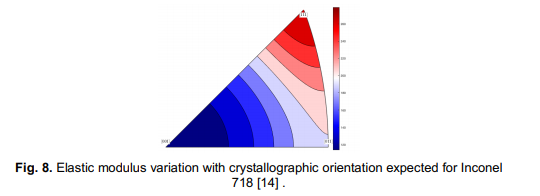

Finally, it is interesting to notice that the reduced elastic modulus maps (Fig. 5d, e and f) do not show a correlation with the local chemical segregation or the temper condition. Instead, the elastic modulus maps present a direct correlation with the crystallographic orientation of the grains (Fig. 2a, b and c). This is not surprising considering the large elastic anisotropy of IN178 [12,13] and the fact that, contrary to hardness, elastic properties are relatively insensitive to microstructural features, such as precipitation stage or small variations in chemical composition. Fig. 8 plots the expected elastic modulus variation with crystallographic orientation [14], calculated using the singlecrystal elastic constants of IN718 (c11=259; c12=179; c44=109.6, in GPa) [12]. The elastic modulus is expected to be much higher in the direction, 279 GPa, than in the and directions, 104 and 113 GPa, respectively. Even though nanoindentation imposes a complex stress state under the indent, it is interesting to notice that the relative values of indentation elastic modulus correlate well with the normal crystallographic orientation of the grains. For instance, the light blue grain in the peak aged condition in Fig. 2b, with the surface normal between [101] and [111], presents the highest elastic modulus, of around 210 GPa (Fig. 5e and 6c), while the dark orange grain in the overaged condition (Fig. 2c), with its surface normal close to [001], presents the lowest elastic modulus, of around 165 MPa (Fig. 5f and Fig.6c).

4. - Conclusions A high-throughput correlative study of local mechanical properties, chemical composition and crystallographic orientation has been carried out in selected areas of cast Inconel 718 specimens subjected to three different tempers. The specimens showed a strong Nb segregation at the scale of the dendrite arms, with local Nb contents that varied between 2 wt.% in the core of the dendrite arms to 8 wt.% in the interdendritic regions and 25 wt.% within the second phase particles (MC carbides, Laves phases and δ phase needles). The nanohardness was found to correlate strongly with the local Nb content and the temper condition in each case. On the contrary, the indentation elastic moduli was not influenced by the local chemical composition or temper condition, but directly correlated with the grain orientation, due to the with high elastic anisotropy of nickel. Determining the correlation between the local mechanical properties, the chemical composition and the temper state can be a very valuable tool to assess the quality of cast components and other solidification processes, such as welds, repairs or 3D printed components. This way the local hardness maps can be directly correlated to the local microstructure, to identify areas with a strong Nb segregation or with local tempers, as a result of heat affected zones.