Products

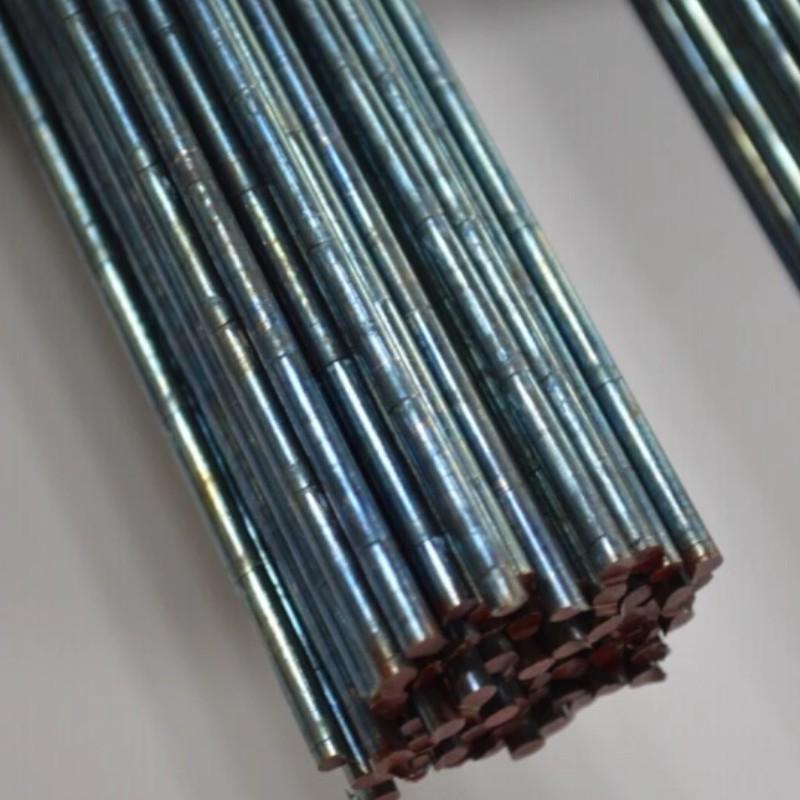

Stellite®1 precision casting,Production process of silica sol(Stellite®1,Alloy 1,UNS R3001)

Five Advantages Of Products

- Has excellent wear resistance

- Has excellent application corrosion resistance

- With high temperature resistance

- Very suitable for very low angle erosion and severe wear

- The typical electrode potential in seawater is about -0.4 V (SCE)

Product Details

Stellite®1 is a surface hardening alloy with excellent wear resistance and corrosion resistance. It retains its over-temperature hardness at 760°C (1400°F).

The material contains a high proportion of hard wear-resistant primary cemented carbide. This alloy is very suitable for applications involving very low angle corrosion and severe wear. Stellite®1 is more sensitive to cracks than other Stellite® grades. People should be careful to minimize the cooling stresses encountered during casting and surface hardening.

Stellite®1 application field

•Pump Sleeves

• Rotary seal rings

•wear pads

•expeller screws

•bearing sleeves.

Stellite 1 Chemical Analysis

C:2 - 3 %

Si:1.20%

Cr:28 - 32%

Fe:1%

Co:57%

W:11 - 13%

Ni:1%

Other:1.50%

We are a direct manufacturer. Castings, pumps and valves can be customized according to drawings. Our most favorable specification is more than 5kg/piece, and there is no minimum minimum requirement. Users are welcome to try to order.

The capacity of our vacuum casting furnace is: 50kg, 100kg, 1000kg.

SHANGHAI CONLY VALVE CASTING CO., LTD

Contact Person: Una

Telephone: +86 17717022732

Landline: +86 021-5995 8756

Company Address: Building 5, No.2800 Caoxin Highway, Xuxing Town, Jiading District, Shanghai

Website: www.condlycasting.cn

Previous: Stellite®12 precision casting,Pr...

-

Hastelloy™C4 precision casting,Production process of sil...

-

Inconel™738 precision casting,Production process of sili...

-

Hastelloy™B2 precision casting,Production process of sil...

-

Monel™400 Precision casting, Production process of silic...

-

Incoloy™825 casting,Precision casting, Production proces...

-

Monel™K-500 precision casting, valve body casting, silic...

-

Inconel™713 precision casting, valve body casting, silic...

-

Incoloy™800H casting,Precision casting, Production proce...