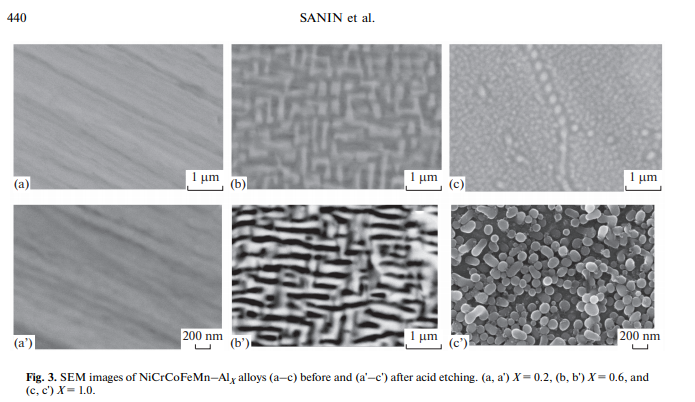

The analysis of structural constituents of the obtained alloys showed that these HEAs consist of two phases: a solid solution based on γ/α-Fe and a solid solution based on β-phase (NiAl intermetallic compound).

The size of structural constituents (~50–100 nm) makes it impossible to collect EDS data. In this regard, it was of interest to study the composition of matrix and dispersive nanoprecipitates. The obtained nanoscale composite structure is atypical of the studied HEAs and, in the future, such compositions can be used as structural materials for various applications.

Synthesis of Cast NiCrCoFeMn–(Ti–Si–B(C)) HEAs

The preparation of cast HEAs reinforced with silicon boride using the introduction of a complex modifier based on Ti–Si–B (C) system into the green mixture by metallothermic SHS method was first studied. The main aim is to provide a controlled phase composition and obtain a given structure consisting of HEA matrix (Co–Cr–Fe–Ni–Mn) and strengthening precipitates based on metal borides and silicides (Ti(Cr)C, Ti(Cr)B2, Ti5Si3, etc.). Most of the elements included in the studied composition are reactive and can have a mutual influence on the occurrence of chemical reactions during the interaction of the composition in the combustion wave. It should be noted that NiCrCoFeMn HEA, also known as Cantor alloy, forms the basis of what is now referred to as the family of HEAs and is multiphase. However, it was previously shown that NiCrCoFeMn alloy, including one prepared using metallothermic SHS [33, 34], possesses low strength properties [4]. Therefore, the formation of new structural elements can improve the strength properties of HEAs of the Co–Cr–Fe–Ni–Mn system. In this context, particular attention was given to determining and testing the synthesis regimes of Co– Cr–Fe–Ni–Mn HEAs strengthened by silicon boride using the introduction of Ti–Si–B (C) complex modifier.

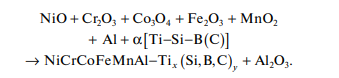

The SHS reaction can be represented by the following scheme:

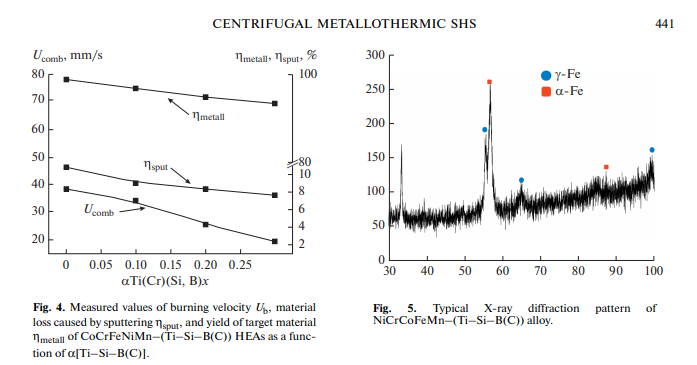

A video record of combustion process of studied compositions demonstrated that, for α = 0–8 wt %, the green mixture was able to burn and, as a result, the cast combustion products were formed. However, for α = 6–8 wt %, the prepared samples exhibited low plasticity and fractured under impact. SEM studies of these alloys revealed the precipitates of carbide and boride phases in the bulk of material, including complex intermetallic compounds, which apparently is the reason for the increased brittleness. Thus, we can conclude that the compositions with α < 6% are more promising for further investigation.

For α < 6% and a > 30 g, ingots with clear phase separation were formed. An increase in α led to a noticeable decrease in the burning velocity (Fig. 4).

It is known that NiCrCoFeMn HEAs have a single-phase structure and possess increased plasticity [3–6]. The introduction of α[Ti–Si–B(С)] into the composition of green mixture makes it possible to control the formation of composite structure consisting of homogeneous matrix based on HEAs and strengthening structural inclusions. The controlled addition of “light” components reduces the density of obtained HEAs and increases their physicomechanical characteristics. The simultaneous introduction of silicon and boron contributes to an increase in the oxidation resistance of alloys.

In experiments on changing the centrifugal acceleration within the range 20–70 g, the optimal range of 65 ± 5g for the synthesis of alloys of this system was found. The increased values of a (in comparison with previous studies) are explained by the present of refractory components such as borides and silicides in the composition.

Figure 5 shows the XRD pattern typical of NiCrCoFeMn–(Ti–Si–B(C)) HEAs. The alloys consist only of two phases: α-Fe (bcc) and γ-Fe (fcc). XRD analysis revealed no additional phases. Apparently, the concentration of structural precipitates was below the sensitivity limit of the method. An increase in the complex modifier content leads to an insignificant change in the fractions of formed solid solutions.

SEM images presented in Fig. 6 indicate homogeneous structures of NiCrCoFeMn alloys obtained with Ti–Si–B (C) additive. Element maps (Figs. 7–9) revealed new structural precipitates in the matrix.