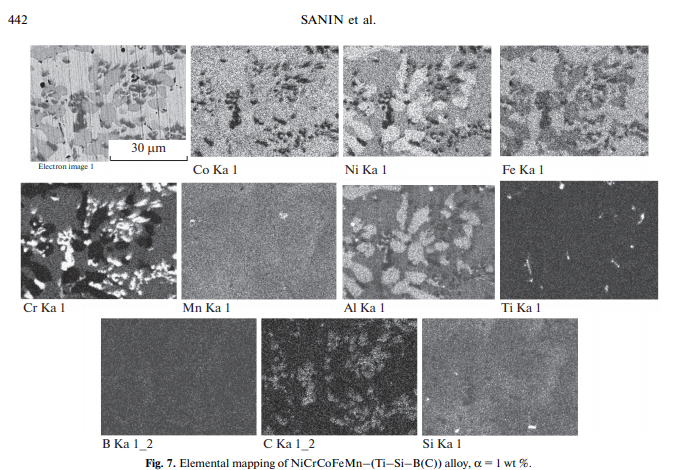

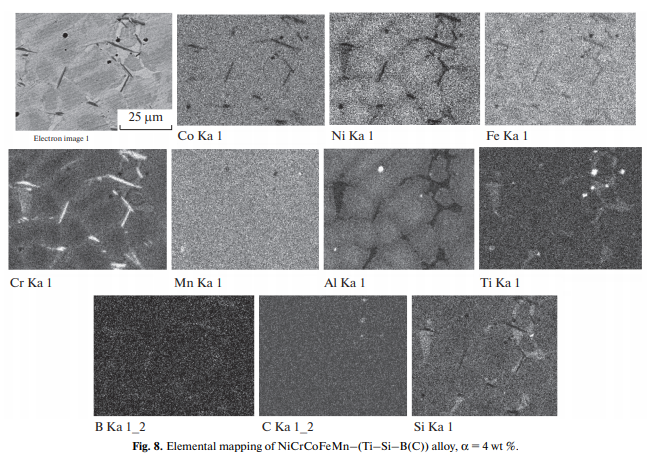

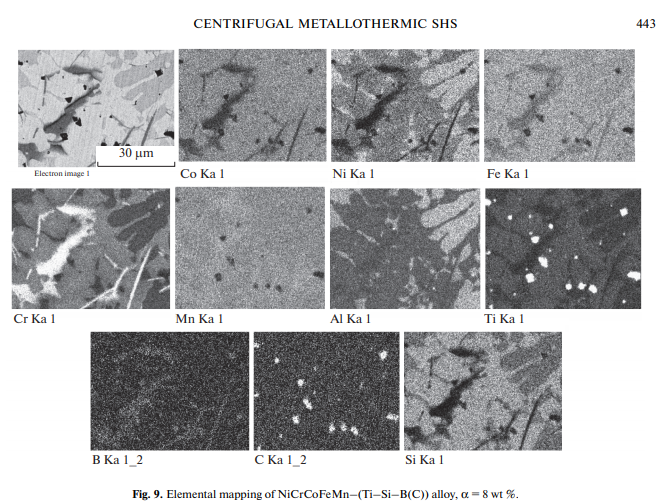

Their combination, location, and morphology depend on the amount of Ti–Si–B (C) additive. In the case of low additive concentration (Fig. 7), the equiaxed precipitates of the phase enriched with chromium and silicon and fine individual titanium carbide particles are observed. Boron is seen to distribute uniformly over the entire bulk. For α = 4 wt % (Fig. 8), the morphology of precipitates of the phase enriched with chromium and silicon changes from equiaxed to platelike. Pronounced Al-enriched inclusions are formed. Apparently, this is a consequence of the fact that the introduced components (Ti, B, Si) partially take part in the reduction reaction. As a result, part of Al not involved in the reduction process falls into the target products, forming zones of increased Al concentration, which coincides with increased Ni concentration ones. A further increase in α[Ti–Si–B(С)] changes the structure (Fig. 9). The structure is seen to contain precipitates of boride (Cr–Bx), carbide (Ti–Cx), and silicide (Ti (Cr)–Six) phases.

Thus, the microstructural analysis shows that the added Ti, Si, and B components are predominantly concentrated in chromium-enriched regions. Fe, Ni, Co, and Mn form a matrix. The observed structure of HEAs may be of practical interest.

CONCLUSIONS

Cast Co–Cr–Fe–Ni–Mn high-entropy alloys reinforced with silicon boride were first prepared by centrifugal SHS from metallothermic compositions containing a complex modifier Ti–Si–B (C). The composition of NiCrCoFeMn–(Ti–Si–B (C)) alloys contains all target elements uniformly distributed over the bulk of ingot. An increase in the additive content leads to the precipitation of particles of titanium carbides and borides in the matrix based on HEA. The morphology and concentration of such precipitates depend on the amount of additive.

NiCrCoFeMn–AlX alloys, where X is varying from 0.2 to 1, are studied. The alloys synthesized with high Al concentration (X > 0.6) are represented by a hierarchical structure. The composite structure was found to contain NiAl as a basis and dispersive nanoprecipitates (~100 nm) of solid solution based on Cr and Fe.

The experimental data allow us to draw the conclude that the HEAs under study and the proposed method for their preparation seem promising. The method of preparing metal composite materials with a given structure can be readily suggested as a method for producing new HEAs with enhanced performance characteristics.