Dissatisfaction with casting results often prompts us to rethink our workflow and improve our original machining methods. The series of casting tests carried out in this paper resulted from the fact that when a particularly large pontic was cast using remaniumstar alloy, although the surfaces of the individual crowns were smooth, the majority of the pontic units were rough. Overheated alloys cannot be used during casting for large fixed bridges. The design and placement of the sprues adopts the traditional method: the sprue with a diameter of 3mm is used for the crown, the 3.5mm sprue is used for the bridge, and the 5mm is used as a transverse sprue to connect these sub-sprues. The diameter of the main sprue is 4mm. In the following, it will be described in detail what methods and steps are used to obtain a smooth and uniform surface of the casting.

Preparation for casting test

A prerequisite for smooth casting surfaces is the use of fine-grained embedding materials, such as remaCC for crown and bridge technology. In the initial casting test, a thick wax rod with dimensions of approximately 60mm long, 9mm high and 3mm wide was selected, which is similar to the cut rod structure on the implant. Another purpose of the test is to cast bulky fixed bridges without shrinkage cavities, such as those used in the molar area.

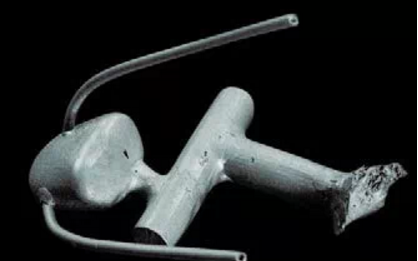

Figure 1: Tested cast "rod" with rough surface and preheated at 950°C.

Figure 2: Tested cast "rod" with smooth surface and preheated at 800°C

Figure 3: Test casting "rod" with sprue inserted.

Test casting "rods"

Figure 1 shows the first casting test. The surface of the casting is covered with fine air bubbles, which is the damage caused by the embedding material to the surface of the casting in the embedding cavity. 60g of remaniumstar alloy was used in all castings, which corresponds to a weight of approximately 140g of precious metal alloy. Various sprue designs and placement methods were tried during the casting process. At the beginning of the test, the preheat temperature of the casting was set at 950°C. High-frequency centrifugal casting machines are used in the casting process, of course, vacuum pressure casting machines can also be used. Using the exhaust duct with a diameter of 1.2mm and observing under the relatively low preheating condition of the Mau Fu furnace, how far the alloy melt can be thrown out by applying the fine sprue under the action of centrifugal force. The preheat temperature was successively reduced by 50°C in each subsequent casting test. Judging by the smoothness of the casting surface and the formation of shrinkage cavities, it was found that the best casting results were produced at a preheating temperature of 800 °C (Figure 2). Even when the furnace temperature is set at 850°C, the surface of the casting will still appear slightly rough under the condition of using the same weight of alloy. The placement of the sprue adopts the method of casting the bridge. Why this design is needed will be further explained in a later article. The casting model uses the shape of a wax rod, on which 4 sprues with a diameter of 3.5mm are placed directly. A 5mm transverse sprue was placed 10mm from the casting as a gold reservoir and connected to the main sprue (Fig. 3).

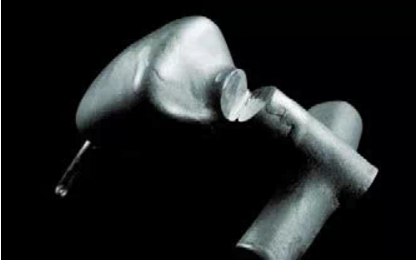

Figure 4: Cast bridge with significant suction shrinkage despite the use of a gold reservoir, preheated at 950°C.

Fig. 5: Cast bridge, changing the position of the gold reservoir, disappearance of suction shrinkage cavities, preheating temperature of 800°C.

Test casting "bridge"

Figure 4 shows the use of a 5mm diameter transverse sprue connected to a 3.5mm sprue at a distance of 2.5mm from the bridge. Despite the use of a preheat temperature of 950°C, the roughness of the bridge surface was not as pronounced as that of the cast rod. Of course the amount of 9g cast metal used is also far less than the amount of the test cast rods. The undesired point is that significant suction cratering occurs despite the use of the gold reservoir. According to the results of the previous casting test, the position of the sprue as the gold storage pool was set at 10mm from the bridge body and connected to the main sprue. A cross-section of the runner after casting (Fig. 5) shows that the function of the gold reservoir is well utilized using this method. When the preheating temperature is set at 800℃, the surface of the bridge also produces the best casting effect. A sprue with a diameter of 3.5mm is directly guided to ensure that the alloy melt can be injected into the mold quickly. In the absence of a separate sprue, it can also ensure that the injected melt will not produce greater turbulence in the mold.

Test casting "fixed bridge"

In addition to the improved surface of the casting (Fig. 6), it was shown that, under the given casting conditions, even when the preheat temperature was reduced to 800 °C, the casting alloy melt could be sufficiently injected to the edge of the crown and Sharp edges are formed (Figure 7). The formation of a rounded crown edge indicates that the alloy melt solidifies too quickly. Figure 8 shows that when casting a 13-unit fixed bridge, it is not necessary to place a sprue on each bridge unit. A 3.5mm sprue can be placed between adjacent crowns and bridges. According to the experience of the previous test, the sprue as the gold reservoir should also be placed accordingly (Fig. 9). This method facilitates separation of the sprue after casting and reduces the risk of perforation of the crown during separation and grinding. Compared with precious metal alloys, the grinding loss generated when machining cobalt-chromium alloys is completely negligible. Of course, there is also a disadvantage of using straight sprues in long-span long fixed bridges, that is, the wax model is not as stable as the addition of horizontal sprues when it is removed, but despite this, the fit of the casting is still very accurate (Fig. 10).