1. Domestic production status of nickel and nickel-based alloys

Pure nickel for domestic industrial use can be produced on its own, but some nickel-based alloys mainly rely on imports.

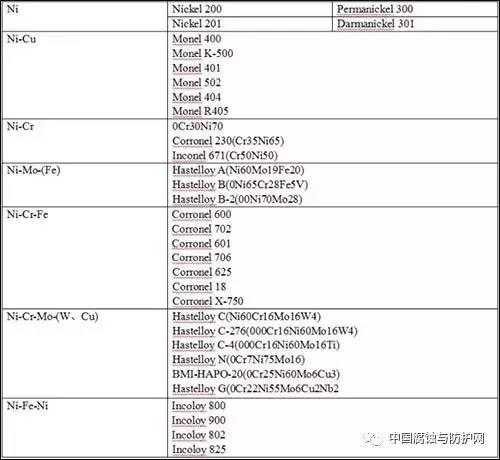

Types of nickel and nickel-based alloys (some have national material standards)

Commonly used nickel and nickel-based alloy models are: pure nickel N6; Monel 400; Hastelloy B, Hastelloy B-2; Hastelloy C-276, etc.

2. Corrosion resistance of nickel and nickel-based alloys

Nickel has a greater tendency to turn into a passive state. At normal temperatures, the surface of nickel is covered with an oxide film, which makes it resistant to corrosion in water and many salt solutions.

Nickel in non-oxidizing dilute acids, such as <15% hydrochloric acid, <17% sulfuric acid and many organic acids, is quite stable at room temperature. However, when oxidants (FeCl2, CuCl2, HgCl2, AgNO3, and hypochlorite) and ventilation are added, the corrosion rate of nickel increases significantly.

Nickel is completely stable in all alkali solutions, whether it is high temperature or molten alkali, which is an outstanding characteristic of nickel.

Monel is more corrosion-resistant than nickel in reducing media, and more corrosion-resistant than copper in oxidizing media, and more corrosion-resistant than nickel and copper in phosphoric acid, sulfuric acid, hydrochloric acid, salt solutions and organic acids.

In any concentration of hydrofluoric acid, Monel alloy is very resistant to corrosion when oxygen enters a little. But when there is aeration and oxidant in the solution, or when there are harmful impurities such as iron salt and copper salt in the solution, its resistance to hydrofluoric acid will decrease. In addition to platinum and silver among metal materials, it is one of the best materials resistant to hydrofluoric acid corrosion.

It is very resistant to corrosion in caustic alkali solution, but when the concentration of sodium hydroxide is high, the corrosion resistance of Monel alloy is worse than that of nickel, but it is still more alkali resistant than other metal materials.

Monel alloy is prone to stress corrosion cracking. It is best to use it after annealing at 530-650℃ to eliminate stress.

Hastelloy alloys commonly used are Hastelloy B (B-2, B-3) and Hastelloy C-276, which have high corrosion resistance in non-oxidizing inorganic and organic acids, such as resistance to dilute at 70°C. Sulfuric acid, resistant to all concentrations of hydrochloric acid, phosphoric acid, acetic acid and formic acid, especially heat-resistant concentrated hydrochloric acid.

Hastelloy is stable in caustic alkali and alkaline solutions, and completely stable in organic media, sea water and fresh water.