Abstract

A high-throughput correlative study of the local mechanical properties, chemical composition and crystallographic orientation has been carried out in selected areas of cast Inconel 718 specimens subjected to three different tempers. The specimens showed a strong Nb segregation at the scale of the dendrite arms, with local Nb contents that varied between 2 wt.% in the core of the dendrite arms to 8 wt.% in the interdendritic regions and 25 wt.% within the second phase particles (MC carbides, Laves phases and δ phase needles). The nanohardness was found to correlate strongly with the local Nb content and the temper condition. On the contrary, the indentation elastic moduli was not influenced by the local chemical composition or temper condition, but directly correlated with the crystallographic grain orientation, due to the high elastic anisotropy of nickel alloys.

1. Introduction

Cast and forged In718 polycrystalline Ni-base superalloys present high temperature strength and fatigue resistance even in oxidizing and corrosive environments [1]. Such performance makes this material suitable for use as turbine discs and some static components of aero-engines working at temperatures up to 600-700 ºC [2]. The formulation of this alloy includes various transition metals which lead to strengthening by solid solution, precipitation via several second phase particles, γ', γ'', δ (Ni3Nb), MC carbides and Laves phases, as well as grain size refinement and a high twin boundaries density [3]. In casting processes, chemical segregation occurs during the solidification stage leading to local variations in the mechanical properties of the material at the microstructural scale that have not been studied before.

The recent advances in high-speed nanoindentation mapping methods, such as XPM (accelerated property mapping) [4], enable evaluating local variations in the mechanical properties of large areas with lateral resolutions of a few micrometres. Such resolution values are similar to those typically selected in electron microscopy techniques for determining the local composition and the crystallographic orientation, such as EDS (electron dispersive X-ray spectroscopy) and EBSD (electron back scatter diffraction), respectively. Hardness is usually determined as the ratio between the maximum indentation load and the projected area of the residual imprint [5]. Nevertheless, when the indentation depth ranges from nanometres to a few micrometres such task becomes tedious, especially in the case of high-speed nanoindentation maps where the aim is to measure thousands of indentations. This issue can be addressed by depth-sensing instrumented indentation, where the indentation load (P) and the penetration depth (d) of the indenter are continuously recorded. Provided that the geometry of the indenter is known, the hardness and elastic modulus can be directly inferred from the indentation load-penetration curves using the Oliver and Pharr method [6]. In the case of high-speed nanoindentation maps is, however, important to keep track of the indenter geometry during the process, because this can be altered by tip wear over the thousands of indentations involved in the maps.

In this study, we correlate the XPM maps with the crystallographic orientation obtained by EBSD and the compositional maps obtained by EDS of selected areas of cast Inconel 718 specimens subjected to three different tempers. The EDS results showed acute Nb segregation across the dendritic arms and in the interdendritic regions that lead to strong nanohardness gradients in the XPM maps. Nevertheless, the XPM maps show relatively constant elastic moduli inside the grains, not influenced by the local chemical composition but a direct dependence of the grain orientation, as expected for materials with high elastic anisotropy like nickel. Determining the dependence of the local mechanical properties with chemical segregation is key for tailoring the properties of the resulting material during casting or other solidification processes, such us welding, repairing or 3D printing, for optimizing processing parameters and for developing microstructure based models.

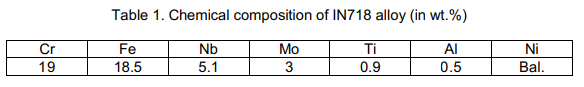

2. - Results 2.1.- Microstructure The material used in the present study was a cast IN718 polycrystalline Ni-base superalloy, with the average composition shown in Table 1.